Ƙirƙirar Ƙwararrun Latsa CNC

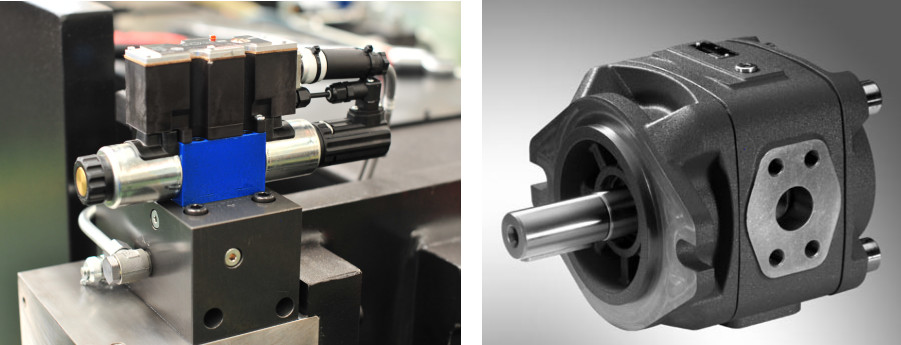

1.Electro-na'ura mai aiki da karfin ruwa tsarin da aka soma don sarrafa dual cylinders don samun high aiki tare daidaita daidaito, high lankwasawa daidaito, da kuma repositioning daidaito.

2. The inji deflection atomatik ramuwa tsarin da aka soma don warware tasirin nakasawa na darjewa a lokacin lankwasawa tsari a kan ingancin workpiece. Ana daidaita adadin diyya ta atomatik ta tsarin CNC don sauƙaƙe daidaito.

(1) Ana biya na'ura ta hanyar daidaitawa ta hanyar daidaitawa ta hanyoyi biyu, wanda zai iya gamsar da diyya na madaidaiciya da madaidaiciyar shugabanci na inji.

(2) Ana ɗaukar hanyar ramawa mai yawa don sanya daidaiton lanƙwasawa ya fi daidai.

(3) da lankwasawa na wannan farantin kauri abu diyya sau ɗaya a wurin, daban-daban daga na'ura mai aiki da karfin ruwa ramuwa da kuma baya da kuma gaba motsi na tsarin, inji diyya ƙwarai rage inji kayan aiki workbench gajiya nakasawa, inganta ta sabis rayuwa;

(4) Yi amfani da mai ragewa na musamman da babban madaidaicin potentiometer don sarrafa daidai sarrafa daidaiton ramuwa.

(5) Daban-daban daga uku-farantin tsarin na na'ura mai aiki da karfin ruwa rama worktable, wannan na'urar rungumi dabi single-farantin worktable zane, wanda zai iya yadda ya kamata hana tsangwama a lankwasa workpiece.

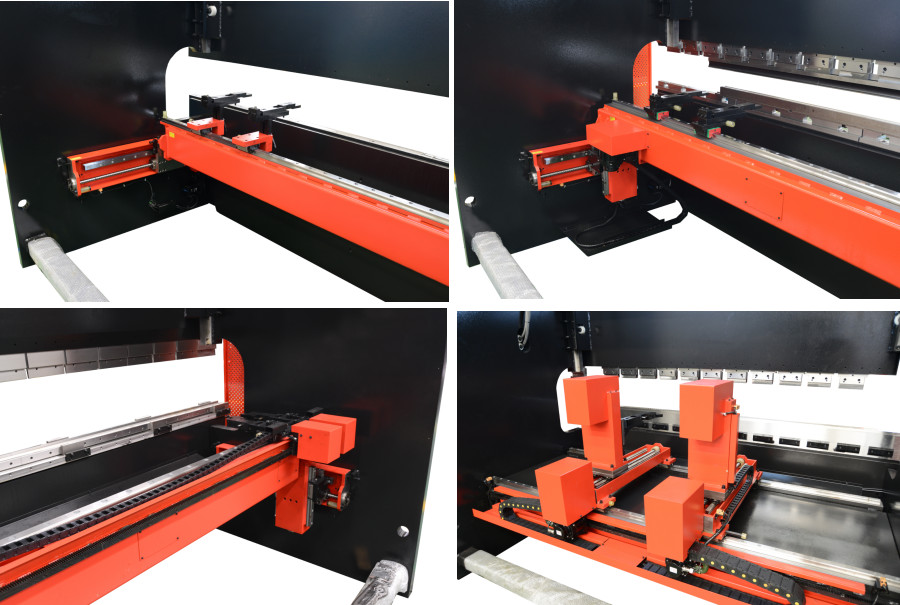

3. Multi-functional backgauge wanda za a iya fadada shi zuwa ga gatari guda 6, watau X1 da X2 axes na baya da gaba, R1 da R2 na sama da kasa da Z1 da Z2 na hagu da dama. The workpiece lankwasawa za a iya gane flexibly.

4. An haɗa firam ɗin a cikin lokaci ɗaya bayan waldawa, ana sarrafa shi ta hanyar CNC pentahedron cibiyar sarrafawa, yana tabbatar da daidaito da daidaiton aiki na firam.

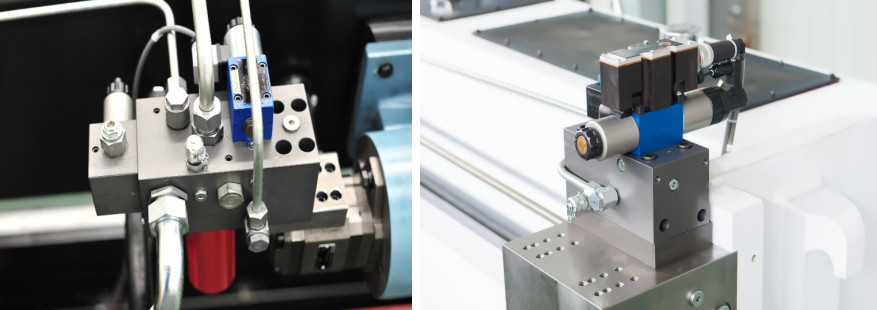

5. Haɗe-haɗen tsarin kula da hydraulic yana rage bututun mai, don haka yana guje wa ɗigon mai kuma yana inganta kwanciyar hankali na aikin, kuma an ƙawata bayyanar injin.

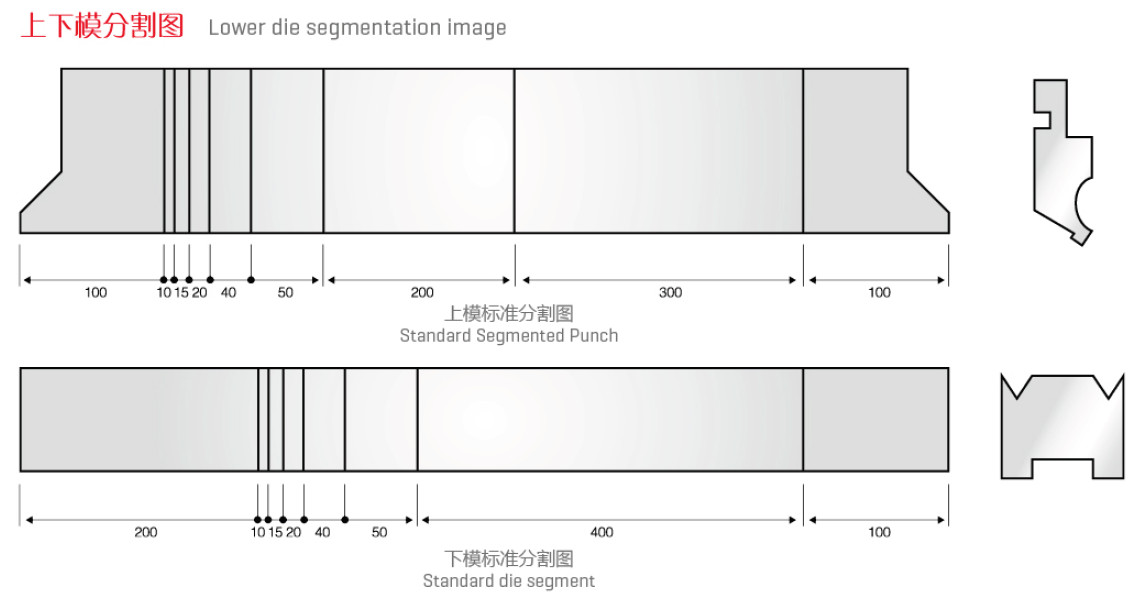

6. Segmented naushi za a iya hade tare da wani tsawon bisa ga lankwasawa da ake bukata na musamman workpiece.

7.Hydraulic punch auto clamping ko makaniki mai sauri clamping za a iya sanye take a matsayin wani zaɓi don rage yawan aiki da kuma inganta aiki yadda ya dace.

8. Tsarin CNC yana ɗaukar tsarin Delem CNC. An nuna wannan tsarin CNC tare da sabon da'irar lantarki, nunin TFT launi na gaskiya tare da babban ƙuduri da menu na harshe da yawa. Yana da tsarin sarrafa aji na farko don na'ura mai lankwasa a duniya.

9. An shigar da na'urar diyya nau'in C nau'in makogwaro a ƙarƙashin makogwaro na kayan aikin injin, wanda aka haɗa tare da na'urar ganowa. Ƙananan nakasawa na ƙarfin lanƙwasa ba zai shafi daidaitattun ma'auni na tsarin ba, kuma za'a iya tabbatar da ma'auni na kowane kauri da kowane farantin kayan aiki.

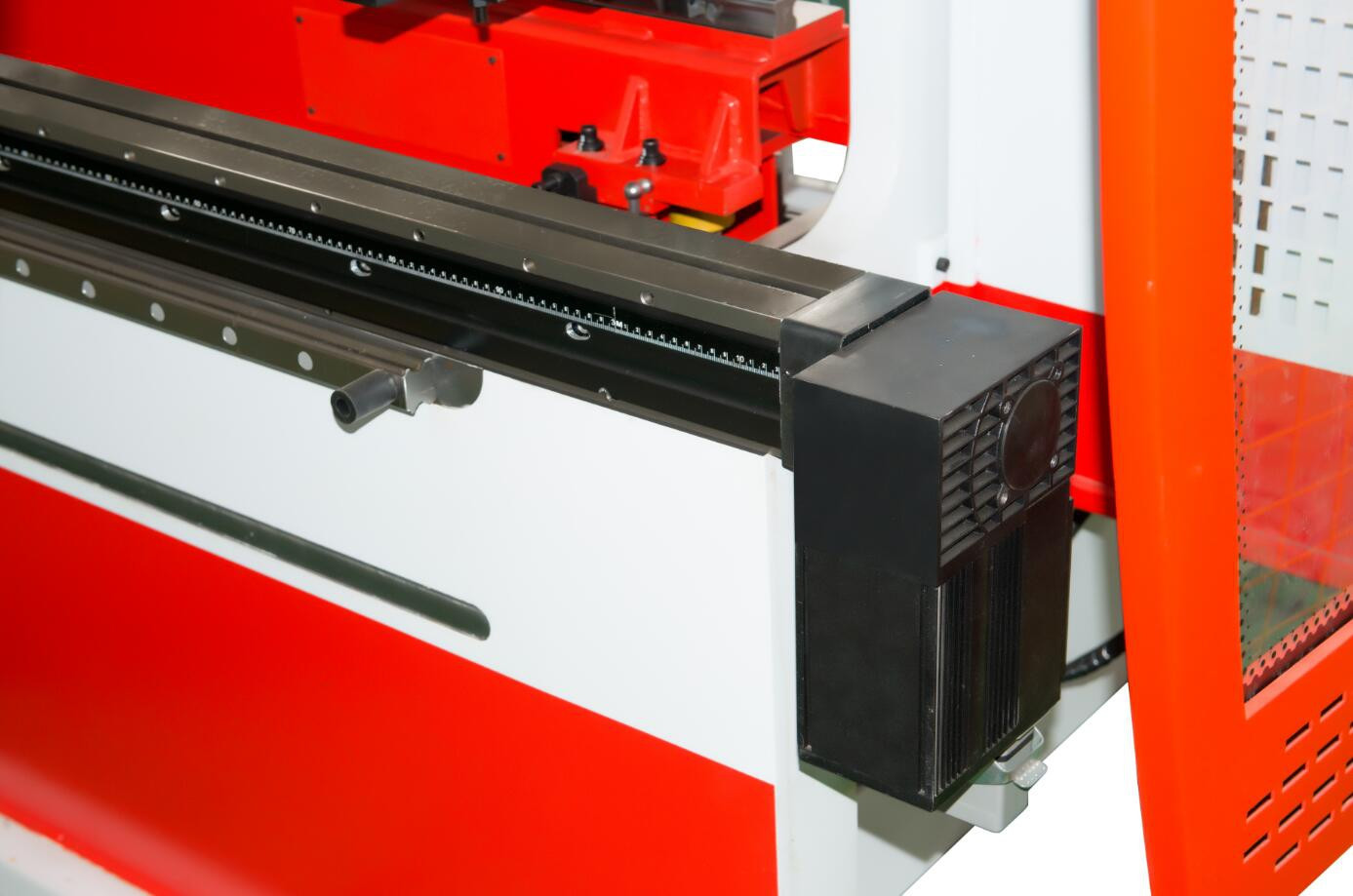

10, Magoya bayan gaba da jagorar layi suna sa motsi ya fi sauƙi

Delem DA66T CNC tsarin kula da matakin ci gaba na duniya

1. Cikakken tsarin aiki na WINDOWS®, na iya gane rufewar injin nan take;

2. Zaɓin harsuna da yawa tare da aiki mai dacewa;

3. Zane mai kyan gani na gaye tare da aiki na mutane;

4. Tsarin ƙirar ƙirar fasaha, tsarin za a iya ƙarawa zuwa gatari 24;

5. 17 "TFT gaskiya launi LCD nuni, 2D mai hoto shirye-shirye;

6. Gina-in PLC don rage ƙirar kewayawa da haɓaka aminci;

7. USB linzamin kwamfuta tashar jiragen ruwa, keyboard tashar jiragen ruwa;

8. Atomatik tara na inji aiki lokaci da lankwasawa;

9. Hanyar lankwasawa ta atomatik tari da kuma lankwasawa;

10. Zuƙowa kyauta daga bayyanar injin, kayan aiki da kayan aiki a cikin ƙimar 1: 1: 1 tare da tsarin hoto;

11.Digital, graphic da sauran hanyoyin mutu shirye-shirye, lebur mutu, manyan baka mutu, Multi V tsagi mold, m V tsagi mold;

12, bayanan gyare-gyaren kusurwa ta atomatik, tebur na jure juriya na koyon kai da aikin gano karo na gaba ɗaya, kawar da samfuran sharar gida;

13. Kuskuren tsarin ƙararrawa don guje wa mummunan aiki;

14. Ƙwaƙwalwar ƙwaƙwalwa 1G

15. Bincike mai nisa;

16. Injin bincike na musamman software, saka idanu na ainihi;

17. Software na shirye-shirye na musamman ba tare da layi ba na iya rage lokacin shirye-shirye da haɓaka aiki;

18. shigar da tsarin sarrafa fayil, editan rubutu;

19. Aikin Tandem;

20. Aiki panel sanye take da gaggawa tasha, manual motsi slider da ergonomics hangen zaman gaba.

Saukewa: T-3500TCNC

1 Yi amfani da tsarin aiki na WINDOWS na ainihi, zai iya gane kashewar nan take;

nau'ikan zaɓuɓɓukan harshe guda 2, ana iya saita su zuwa ƙirar Ingilishi, mai sauƙin aiki;

3 salon zane, mai sauƙin aiki, yana nuna madaidaitan mutane;

4 daidaitaccen axis hudu, ƙarin kayayyaki, yana tallafawa har zuwa axis shida;

5.10 "TFT gaskiya launi allo, LCD tabawa, Multi touch, biyu-girma graphics shirye-shirye, 3D nuni;

6 ginanniyar aikin PLC, rage ƙirar kewaye, haɓaka amincin;

7.USB linzamin kwamfuta, keyboard dubawa;

8 lokutan aiki ta atomatik da lokutan lanƙwasawa;

9, dijital da 2D graphics cikakken tabawa shirye-shirye, lankwasawa tsari 3D view, lankwasawa tsari ta atomatik harhada da lankwasawa simulation;

10. Na'ura siffar, mold da workpiece suna da yardar kaina zuƙowa a cikin 1: 1: 1 bisa ga graphics.

11, dijital, mai hoto da sauran hanyoyin mutuƙar shirye-shiryen mutu, lebur mutu, babban madauwari baka mutu, Multi V tsagi mold, m V tsagi mold;

12. Kuskuren tsarin ƙararrawa don guje wa mummunan aiki;

13. Ƙwaƙwalwar ƙwaƙwalwa 1G

14. Injin bincike na musamman software, saka idanu na ainihi;

15. shigar da tsarin sarrafa fayil, editan rubutu;

16. Tandem aiki;

17. Aiki panel sanye take da gaggawa tasha, manual motsi slider da ergonomics hangen zaman gaba.

CNC Latsa birki; cnc latsa birki na'ura mai lankwasa birki; na'urar buga birki ta ruwa

Holland DELEM DA52 CNC Tsarin

1 Yi amfani da tsarin aiki na lokaci-lokaci WINDOWS, na iya gane rufewar nan take

2. Zaɓin harsuna da yawa tare da aiki mai dacewa;

3. Zane mai kyan gani na gaye tare da aiki na mutane;

4. Tsarin tsari na fasaha na fasaha, tsarin zai iya ƙaddamar da 4 axis a hankali

5.7"TFT LCD nuni;

6. Gina-in PLC don rage ƙirar kewayawa da haɓaka aminci;

7. USB linzamin kwamfuta tashar jiragen ruwa, keyboard tashar jiragen ruwa, RS232 tashar jiragen ruwa, aminci tashar jiragen ruwa PLC;

8. Atomatik tara na inji aiki lokaci da lankwasawa;

9. Shirye-shiryen dijital;

10. Digital yanayin mold shirye-shirye;

11. Rubutun gyaran kusurwa ta atomatik;

12, tsarin gargadi na kuskure don hana rashin aiki;

13, ƙarfin ƙwaƙwalwar ajiya shine 64M;

14, software na bincike na musamman, saka idanu na ainihi;

15, Tandem aiki;

16, kwamitin aiki yana sanye da tasha na gaggawa.

Holland DELEM DA53 Tsarin CNC

1 Yi amfani da tsarin aiki na DELEM-LINUX, zai iya gane rufewar nan take

2. Zaɓin harsuna da yawa tare da aiki mai dacewa;

3. Zane mai kyan gani na gaye tare da aiki na mutane;

4. Tsarin tsari na fasaha na fasaha, tsarin zai iya ƙaddamar da 4 axis a hankali

5. 10"TFT LCD nuni;

6. Gina-in PLC don rage ƙirar kewayawa da haɓaka aminci;

7. USB linzamin kwamfuta tashar jiragen ruwa, keyboard tashar jiragen ruwa, RS232 tashar jiragen ruwa, aminci tashar jiragen ruwa PLC;

8. Atomatik tara na inji aiki lokaci da lankwasawa;

9. Shirye-shiryen taɓawa na dijital;

10. Digital yanayin mold shirye-shirye;

11. Rubutun gyaran kusurwa ta atomatik;

12, tsarin gargadi na kuskure don hana rashin aiki;

13, ƙarfin ƙwaƙwalwar ajiya shine 64M;

14, software na bincike na musamman, saka idanu na ainihi;

15. Tsarin sarrafa fayil ɗin da aka haɗa, editan rubutu

16, Tandem aiki;

17, kwamitin aiki yana sanye da tasha na gaggawa.

| A'a. | Bayani | Yawan | Magana |

| 1 | Fayilolin Ayyuka | Saiti daya | |

| 2 | Inner Hex Socket Spanner | Saiti daya | |

| 3 | Man shafawa | Daya babu. | |

| 4 | Grounding Bolt | Saiti daya | |

| 5 | Daidaita Bolt | Saiti daya | |

| 6 | Kula da ƙafafu | Daya babu. | |

| 7 | Daidaitaccen Kayan aiki | Saiti daya |

1. Mai na'ura mai aiki da karfin ruwa: VG46# mai hana amfani da ruwa mai hana ruwa; kuma yawan man da ake buƙata ya dogara da ƙayyadaddun injin;

2. Ƙarfin wutar lantarki: 380V, 50HZ, canjin wutar lantarki 10% --5%

3. Yanayin yanayi: 0°C - +40°C

4. Zafin muhalli: dangi zafi 20-80% RH (ba condensing)

5. Nisantar tushen jijjiga mai ƙarfi da tsangwama na lantarki

6. Ƙura kaɗan, babu cutarwa ko iskar gas

7. Shirya tushe bisa ga zane na tushe

8. Zaɓi ma'aikacin dangi tare da takamaiman tushen ilimi don tsari na dogon lokaci azaman mai sarrafa injin.

| A'a. | Bayani | Yawan | Magana |

| 1 | Fayilolin Ayyuka | Saiti daya | |

| 2 | Inner Hex Socket Spanner | Saiti daya | |

| 3 | Man shafawa | Daya babu. | |

| 4 | Grounding Bolt | Saiti daya | |

| 5 | Daidaita Bolt | Saiti daya | |

| 6 | Kula da ƙafafu | Daya babu. | |

| 7 | Daidaitaccen Kayan aiki | Saiti daya |

60T

| Ƙayyadaddun bayanai | Naúrar | PR9 060/2550 | |

| Max. Karfin Lankwasa | KN | 600 | |

| Max. Tsawon Lankwasawa | mm | 2550 | |

| Nisa Tambayi | mm | 2150 | |

| Zurfin Maƙogwaro | mm | 350 | |

| Ram Stroke | mm | 215 | |

| Rufe Tsayi | mm | 530 | |

| Gudun Matsowa | mm/s | 200 | |

| Gudun Aiki | mm/s | 18 | |

| Saurin dawowa | mm/s | 200 | |

| Babban Mota | Kw | 7.5 | |

| Tsarin CNC | Holland Delem DA66T ko DA52S ko DA53T ko T-3500T CNC tsarin sarrafa Y1, Y2, X, R, Z1, Z2 gatura da inji rawanin. | ||

| Karfin Tankin Mai | L | 300 | |

| X Axis | Daidaito | mm | ± 0.1 |

| bugun jini | mm | 500 | |

| Gudu | mm/s | 400 | |

| Ƙarfi | Kw | 0.85 | |

| R Axis | Daidaito | mm | ± 0.1 |

| bugun jini | mm | 200 | |

| Gudu | mm/s | 200 | |

| Ƙarfi | Kw | 0.85 | |

| Z1,Z2 Axis | Daidaito | mm | ± 0.1 |

| bugun jini | mm | 1250 | |

| Gudu | mm/s | 1200 | |

| Ƙarfi | Kw | 0.75 | |

| Ƙimar Ƙarfafawa | Tsawon | mm | 3400 |

| Nisa | mm | 1400 | |

| Tsayi | mm | 2510 | |

100T

| Ƙayyadaddun bayanai | Naúrar | PR9 100/3100 | PR9 100/4100 | |

| Max. Karfin Lankwasa | KN | 1000 | 1000 | |

| Max. Tsawon Lankwasawa | mm | 3100 | 4100 | |

| Nisa Tambayi | mm | 2700 | 3700 | |

| Zurfin Maƙogwaro | mm | 420 | 420 | |

| Ram Stroke | mm | 265 | 265 | |

| Rufe Tsayi | mm | 530 | 530 | |

| Gudun Matsowa | mm/s | 220 | 220 | |

| Gudun Aiki | mm/s | 17 | 13 | |

| Saurin dawowa | mm/s | 220 | 150 | |

| Babban Mota | Kw | 15 | 11 | |

| Tsarin CNC | Holland Delem DA66T ko DA52S ko DA53T ko T-3500T CNC tsarin sarrafa Y1, Y2, X, R, Z1, Z2 gatura da inji rawanin. | |||

| Karfin Tankin Mai | L | 350 | 500 | |

| X Axis | Daidaito | mm | ± 0.1 | ± 0.1 |

| bugun jini | mm | 500 | 500 | |

| Gudu | mm/s | 400 | 400 | |

| Ƙarfi | Kw | 0.85 | 0.85 | |

| R Axis | Daidaito | mm | ± 0.1 | ± 0.1 |

| bugun jini | mm | 200 | 200 | |

| Gudu | mm/s | 200 | 200 | |

| Ƙarfi | Kw | 0.85 | 0.85 | |

| Z1,Z2 Axis | Daidaito | mm | ± 0.1 | ± 0.1 |

| bugun jini | mm | 1850 | 2800 | |

| Gudu | mm/s | 1200 | 1200 | |

| Ƙarfi | Kw | 0.75 | 0.75 | |

| Ƙimar Ƙarfafawa | Tsawon | mm | 3450 | 4450 |

| Nisa | mm | 1600 | 1600 | |

| Tsayi | mm | 2750 | 2710 | |

150T

| Ƙayyadaddun bayanai | Naúrar | PR9 150/3100 | PR9 150/4100 | |

| Max. Karfin Lankwasa | KN | 1500 | 1500 | |

| Max. Tsawon Lankwasawa | mm | 3100 | 4100 | |

| Nisa Tambayi | mm | 2700 | 3700 | |

| Zurfin Maƙogwaro | mm | 420 | 420 | |

| Ram Stroke | mm | 265 | 265 | |

| Rufe Tsayi | mm | 530 | 530 | |

| Gudun Matsowa | mm/s | 180 | 180 | |

| Gudun Aiki | mm/s | 11 | 11 | |

| Saurin dawowa | mm/s | 150 | 150 | |

| Babban Mota | Kw | 15 | 15 | |

| Tsarin CNC | Holland Delem DA66T ko DA52S ko DA53T ko T-3500T CNC tsarin sarrafa X, Y1, Y2, R, Z1, Z2 gatura da inji rawanin. | |||

| Karfin Tankin Mai | L | 440 | 600 | |

| Na'urar Tankin Mai | a'a. | 3 | 4 | |

| X Axis | Daidaito | mm | ± 0.10 | ± 0.1 |

| bugun jini | mm | 500 | 500 | |

| Gudu | mm | 500 | 400 | |

| Ƙarfi | kw | 0.85 | 0.85 | |

| R Axis | Daidaito | mm | ± 0.10 | ± 0.1 |

| bugun jini | mm | 200 | 200 | |

| Gudu | mm | 200 | 200 | |

| Ƙarfi | kw | 0.85 | 0.85 | |

| Z1,Z2 Axis | Daidaito | mm | ± 0.10 | ± 0.1 |

| Gudu | mm | 1200 | 1200 | |

| bugun jini | mm | 1850 | 2800 | |

| Ƙarfi | kw | 0.75 | 0.75 | |

| Ƙimar Ƙarfafawa | Tsawon | mm | 3470 | 4470 |

| Nisa | mm | 1720 | 1720 | |

| Tsayi | mm | 2700 | 2710 | |

Farashin 9060

| A'a. | Suna | Samfura | Alamar | |

| 1 | Tsarin CNC | DA66T/T-3500T/DA52S ko DA53T CNC System | Holland DELEM | |

| 2 | Servo Motor | ECMA-E21315RS/SGM7G-09AFC61 | DELTA KO YASAKAWA | |

| 3 | Direba Servo | ASD-B2-1521-B/SGD7S-7R6A00A002 | DELTA KO YASAKAWA | |

| 4 | Tsarin Ruwan Ruwa | Electro-hydraulic tsarin | Jamus Bosch-Rexroth ko Jamus HOERBIGER | |

| Haɗin kai mai aiki tare | a. bawul ɗin matsa lamba | |||

| b. bawul mai aiki | ||||

| c. daidaitattun servo bawul da dai sauransu. | ||||

| Na'ura mai sarrafawa taro taro | a. harsashi bawul | |||

| b. madaidaicin bawul ɗin matsa lamba | ||||

| c. bawul mai zaɓi | ||||

| d. daidai gwargwado decompress bawul | ||||

| e. bawul matsa lamba da dai sauransu. | ||||

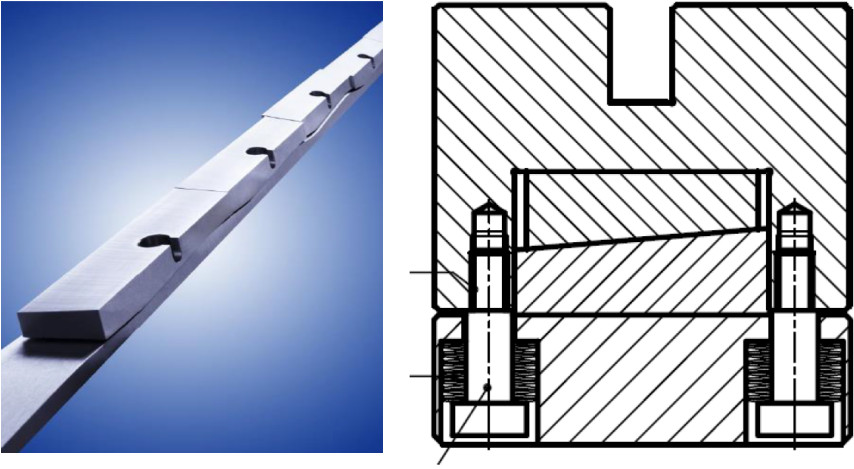

| 5 | Hanyar jagora | 35A--760L KO 35E-760L | THK ko PMI | |

| 6 | Ƙwallon ƙafa | 25/20-1000L ko R25/20-880/1000 | THK ko PMI | |

| 7 | Ruwan mai | PGH3-2X/016RE071VU2 | Jamus Rexroth | |

| 8 | Cikakken saitin zoben rufewa a cikin silinda mai | Amurka PARKER | Amurka PARKER | |

| 9 | Cikakken saitin bututun matsa lamba | 1.GE16 ZSR 3/4EDCF | USA PARKER, EO-2 bututu hadin gwiwa ko Jamus VOSS bututu hadin gwiwa | |

| 2.GE28 LR3/4EDOMDCF | ||||

| 3.W10 ZLCF | ||||

| 4.TH10 ZLR KDSCF | ||||

| 5.WH10 ZSR KDSCF da dai sauransu. | ||||

| 10 | Hadawa | R38 25/42 | Jamus KTR | |

| 11 | AC contactor | LC1-D1810B7, LC1-D0910B7N da dai sauransu. | Schneider | |

| 12 | Maɓallin kusanci | TP-SM5P2 da dai sauransu. | TEND | |

| 13 | Jagorar tasha | UK2.5B, UK10N da dai sauransu. | Phoenix | |

| 14 | Maɓalli | XB2-BVB3LC da dai sauransu. | Schneider | |

| 15 | Yin zane | Holland SIKENS | ||

| 16 | Sarauta | Alamar ƙasa (misali) | SREE/UNION | |

| 17 | Sarauta | Shigo da (zaɓi) | VILLA | |

| 18 | Magoya bayan gaba | misali | JFY | |

Farashin PR9100

| A'a. | Suna | Samfura | Alamar | |

| 1 | Tsarin CNC | DA66T ko DA52S ko DA53T ko T-3500T CNC System | Holland DELEM | |

| 2 | Servo Motor | ECMA-E21315RS/SGM7G-09AFC61 | DELTA KO YASAKAWA | |

| 3 | Direba Servo | ASD-B2-1521-B/SGD7S-7R6A00A002 | DELTA KO YASAKAWA | |

| 4 | Tsarin Ruwan Ruwa | Electro-hydraulic tsarin | Jamus Bosch-Rexroth ko Jamus HOERBIGER | |

| Haɗin kai mai aiki tare | a. bawul ɗin matsa lamba | |||

| b. bawul mai aiki | ||||

| c. daidaitattun servo bawul da dai sauransu. | ||||

| Na'ura mai sarrafawa taro taro | a. harsashi bawul | |||

| b. madaidaicin bawul ɗin matsa lamba | ||||

| c. bawul mai zaɓi | ||||

| d. daidai gwargwado decompress bawul | ||||

| e. bawul matsa lamba da dai sauransu. | ||||

| 5 | Hanyar jagora | 35A-760L KO 35E-760L | THK ko PMI | |

| 6 | Ƙwallon ƙafa | 20/25-880/1000 KO R25/20-880/1000 | THK ko PMI | |

| 7 | Ruwan mai | PGH4-3X/032RE071VU2 | Jamus Rexroth | |

| Saukewa: IPVAP5-32 | Jamus VOITH | |||

| HQI3-32 | Jamus Eckerle | |||

| 8 | Cikakken saitin zoben rufewa a cikin silinda mai | Amurka PARKER | Amurka PARKER | |

| 9 | Cikakken saitin bututun matsa lamba | 1.GE16 ZSR 3/4EDCF | USA PARKER, EO-2 bututu hadin gwiwa ko Jamus VOSS bututu hadin gwiwa | |

| 2.GE28 LR3/4EDOMDCF | ||||

| 3.W10 ZLCF | ||||

| 4.TH10 ZLR KDSCF | ||||

| 5.WH10 ZSR KDSCF da dai sauransu. | ||||

| 10 | Hadawa | R38 25/42 | Jamus KTR | |

| 11 | AC contactor | LC1-D1810B7, LC1-D0910B7N da dai sauransu. | Schneider | |

| 12 | Maɓallin kusanci | TP-SM5P2 da dai sauransu. | TEND | |

| 13 | Jagorar tasha | UK2.5B, UK10N da dai sauransu. | Phoenix | |

| 14 | Maɓalli | XB2-BVB3LC da dai sauransu. | Schneider | |

| 15 | Yin zane | KAILEDI | ||

| 16 | Sarauta | Alamar ƙasa (misali) | SREE/UNION | |

| 17 | Sarauta | Shigo da (zaɓi) | VILLA | |

| 18 | Magoya bayan gaba | misali | JFY | |

Farashin PR9150

| A'a. | Suna | Samfura | Alamar | |

| 1 | Tsarin CNC | DA66T ko DA52S ko DA53T ko T-3500T CNC System | Holland DELEM | |

| 2 | Servo Motor | ECMA-E21315RS/SGM7G-09AFC61 | DELTA KO YASAKAWA | |

| 3 | Direba Servo | ASD-B2-1521-B/SGD7S-7R6A00A002 | DELTA KO YASAKAWA | |

| 4 | Tsarin Ruwan Ruwa | Electro-hydraulic tsarin | Jamus Bosch-Rexroth | |

| Haɗin kai mai aiki tare | a. bawul ɗin matsa lamba | |||

| b. bawul mai aiki | ||||

| c. daidaitattun servo bawul da dai sauransu. | ||||

| Na'ura mai sarrafawa taro taro | a. harsashi bawul | |||

| b. madaidaicin bawul ɗin matsa lamba | ||||

| c. bawul mai zaɓi | ||||

| d. daidai gwargwado decompress bawul | ||||

| e. bawul matsa lamba da dai sauransu. | ||||

| 5 | Hanyar jagora | 35A-760L KO 35E-760L | THK ko PMI | |

| 6 | Ƙwallon ƙafa | 20/25-880/1000 KO R25/20-880/1000 | THK ko PMI | |

| 7 | Ruwan mai | PGH4-3X/032RE071VU2 | Jamus Rexroth | |

| Saukewa: IPVAP5-32 | Jamus VOITH | |||

| HQI3-32 | Jamus Eckerle | |||

| 8 | Cikakken saitin zoben rufewa a cikin silinda mai | Amurka PARKER | Amurka PARKER | |

| 9 | Cikakken saitin bututun matsa lamba | 1.GE16 ZSR 3/4EDCF | USA PARKER, EO-2 bututu hadin gwiwa ko Jamus VOSS bututu hadin gwiwa | |

| 2.GE28 LR3/4EDOMDCF | ||||

| 3.W10 ZLCF | ||||

| 4.TH10 ZLR KDSCF | ||||

| 5.WH10 ZSR KDSCF da dai sauransu. | ||||

| 10 | Hadawa | R38 25/42 | Jamus KTR | |

| 11 | AC contactor | LC1-D1810B7, LC1-D0910B7N da dai sauransu. | Schneider | |

| 12 | Maɓallin kusanci | TP-SM5P2 da dai sauransu. | TEND | |

| 13 | Jagorar tasha | UK2.5B, UK10N da dai sauransu. | Phoenix | |

| 14 | Maɓalli | XB2-BVB3LC da dai sauransu. | Schneider | |

| 15 | Yin zane | KAILEDI | ||

| 16 | Sarauta | Alamar ƙasa (misali) | SREE/UNION | |

| 17 | Sarauta | Shigo da (zaɓi) | VILLA | |

| 18 | Magoya bayan gaba | misali | JFY | |

CNC Latsa birki; cnc latsa birki na'ura mai lankwasa birki; na'urar buga birki ta ruwa