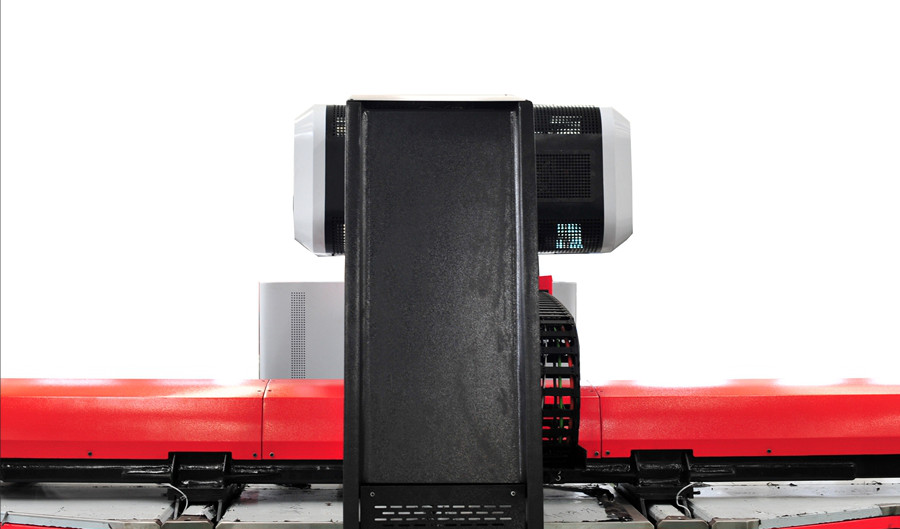

Babban Injin CNC Turret Punch Machine

1. Single servo motor kore tsarin, rungumi dabi'ar babban juyi kai tsaye driven servo motor da kuma tuki naúrar tare da babban obalodi iya aiki don gane low makamashi amfani, high watsa yadda ya dace, abin dogara yi da kuma dace tabbatarwa.

(1) Daidaitaccen gudu da bugun jini

a. Za'a iya zaɓar bugun bugun bugu bisa ga kauri na takardar ta atomatik, inganta ingantaccen aikin.

b. Ana iya daidaita saurin naushi yayin kowane maki na kowane tasha ɗaya,

c. Injin zai iya fahimtar babban saurin gudu yayin wofi gudu da sauri sauri a lokacin Real Punch, kuma babu ainihin ingancin punch, kuma babu da gaske ingancin abin da ake ciki lokacin da.

(2). Siffofin tsarin tare da na'urorin kariya fiye da na yau da kullun da na'urorin kariya masu yawa.

(3). Ana iya daidaita ƙarfin naushi ta atomatik bisa ga kauri da kauri da ragon gudu don sa ingancin naushi ya kai matsayi mai girma.

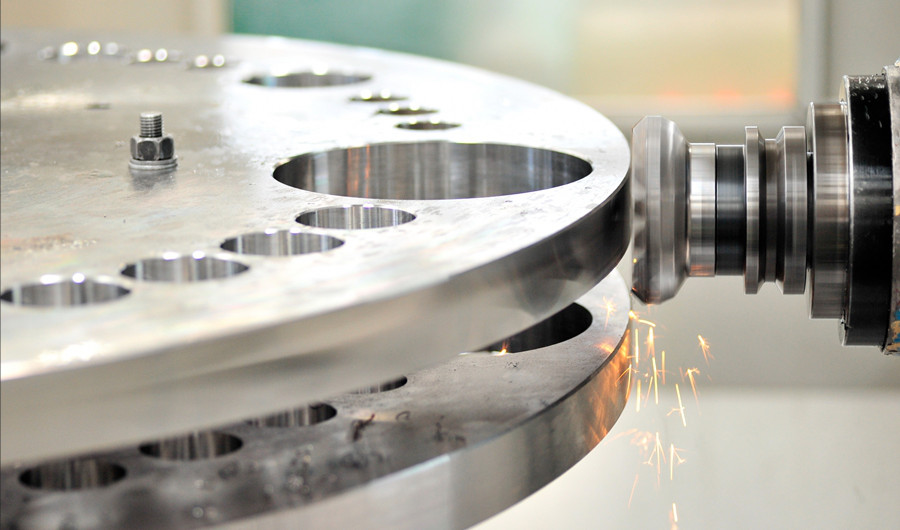

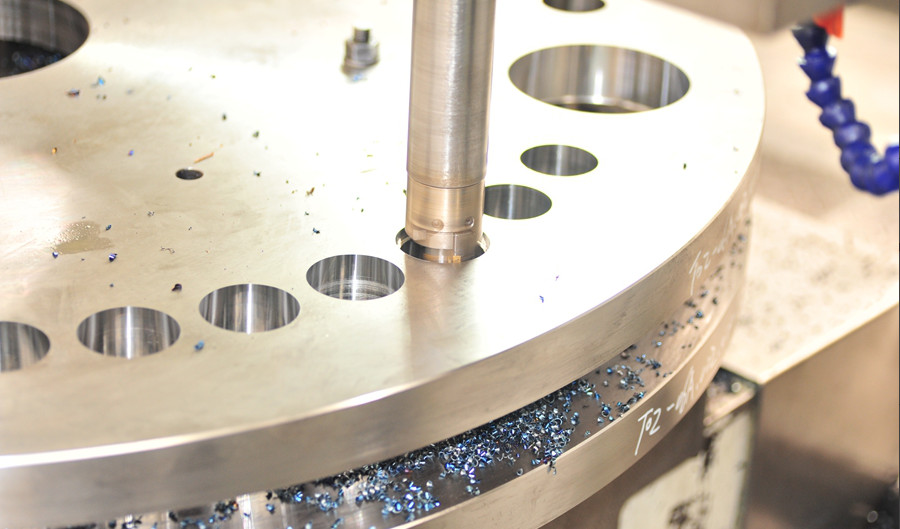

2. Turret tare da bushing ana aiwatarwa a cikin nau'i-nau'i

Ana sarrafa turret ta na'ura na musamman don tabbatar da coaxial na sama da ƙananan turret da fadada rayuwar sabis na kayan aiki; gandun daji mai bushe yana sauƙaƙe tsarin turret don tsawaita rayuwar sabis; Ana iya amfani da dogon kayan aiki don haɓaka daidaiton jagora da faɗaɗa rayuwar sabis ɗin kayan aiki (don takarda mai kauri).

3. Shigo da pneumatic, lubricating da na'urorin lantarki suna tabbatar da amincin duk na'ura.

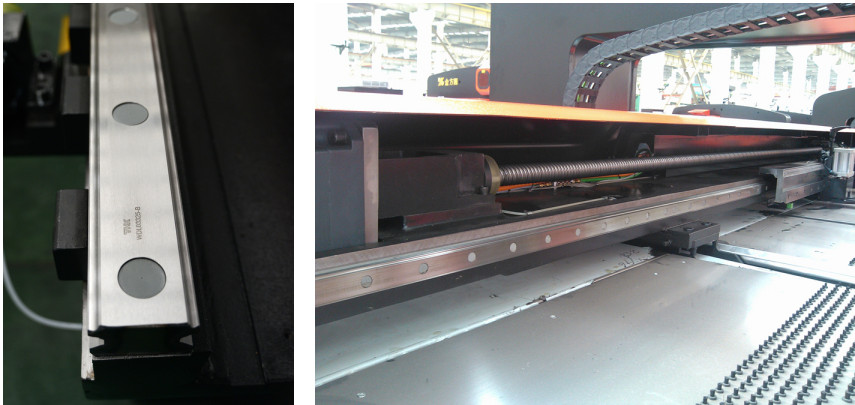

4. Babban jagorar jagora da ƙwallo daga Japan ko Jamus suna tabbatar da daidaitaccen ciyarwa.

5. Hard goga da ball gauraye worktable rage amo da vibration a lokacin Gudu da kuma kare takardar surface.

6. O-type welded frame an girgiza har sau biyu, an share damuwa gaba daya. Cibiyar sarrafa pentahedron ta SHW ce ke sarrafa firam ɗin a lokaci ɗaya, babu buƙatar yin matsayi na biyu.

7. Ƙaƙwalwar ruwa tare da babban ƙarfin ƙwanƙwasa yana tabbatar da kwanciyar hankali; hadedde karusa yana tabbatar da ingantaccen ƙarfi da motsi mai dacewa na matsewa.

8. An nuna tsarin tare da aikin kariya ta atomatik don kauce wa lalacewar kayan aiki da ƙuƙwalwa, tabbatar da ci gaba da gudanar da shirin.

9. The auto-index rungumi dabi'ar high daidai tsutsa dabaran da tsutsa inji, tabbatar da high daidai indexing. Max. tooling diamita iya isa 88.9mm da auto-index za a iya fadada zuwa 4 nos.

10. Haɗe-haɗen tsarin katako don yin jigilar kaya da katako a cikin sashi ɗaya, ƙara haɓakawa kuma yana kawo daidaitaccen matsayi. Injin na iya yin aiki da ƙarfi sosai yayin ciyar da sauri kuma yana kawo ƙarshen karkatar da gatura na X da Y.

11. X axis: yana ɗaukar motar servo don fitar da ma'aikatan ƙwallo daidai kuma an nuna jigilar kaya tare da ƙima mai ƙarfi da ƙima mai nauyi. Y axis: servo motor kai tsaye yana fitar da ragon ciyarwa wanda aka haɗa tare da hanyar jagorar injin, tsaga nau'in katako yana daidaitawa tare da rakodin ciyarwa, kuma za a watsa ƙarfin aiki zuwa injin injin & ƙasa ta hanyar ciyarwa da jagora don rage girgiza kai na katako. An nuna wannan tsarin tare da halaye na mai kyau rigidity, haske a cikin nauyi, ƙananan nauyi, da kyakkyawar amsawa mai ƙarfi a cikin dukan tsarin ciyarwa, barga mai gudu da kuma daidai.

12. An karɓi tsarin lubrication na tsakiya don aika man shafawa na man shafawa zuwa madaidaicin lubricating dangi kai tsaye, rage juzu'i na kowane nau'i na aiki da haɓaka rayuwar sabis.

13. Anti-sheet-deformation canji da takardar-anti-stripping canji aka soma.

| A'a. | Suna | Qty | Magana |

| 1 | Jerin Shiryawa | 1 saiti | |

| 2 | Takaddun shaida mai inganci | 1 saiti | |

| 3 | Manual Aiki na Kanikanci | 1 saiti | |

| 4 | Littafin Aikin Lantarki | 1 saiti | |

| 5 | Zane na tushe | 1 saiti | |

| 6 | Zana Babban Lantarki | 1 saiti | |

| 7 | Takardun Tsarin Software na atomatik | 1 saiti | |

| 8 | Zana Babban Lantarki na DBN | 1 saiti | |

| 9 | Manual kayan aiki | 1 saiti | |

| 10 | CNC tsarin manual | 1 saiti | |

| 11 | Zane kayan aiki | 1 saiti |

| A'a. | Suna | Ma'auni | Qty |

| 1 | Dual-head Spanner | 5.5×7-22×24 | 1 saiti |

| 2 | Spanner mai motsi | 200 | 1 ba. |

| 3 | Socket Head Spanner | S1.5-S10 | 1 saiti |

| 4 | Cross Screwdriver | 100×6 | 1 ba. |

| 5 | Man shafawa | Saukewa: HS87-4Q | 1 ba. |

| 6 | Bindigogi Mai Lubrication Pump Compressor Gun | SJD-50Z | 1 ba. |

| 7 | Bindiga mai ƙarfi | 1 saiti | |

| 8 | T siffar kullin | M14×1.5 | 1 ba. |

| 9 | Canjin kusanci | M12 PNP SN=2 bude | 1 saiti |

| 10 | Canjin kusanci | M12 PNP SN=2 rufe | 1 ba. |

| 11 | Spanner | T09-02,500,000-38 | 1 ba. |

| 12 | Spanner ga gas Silinda canji | 1 saiti | |

| 13 | Bututu mai laushi | Ø 12 | 1 ba. |

| 14 | fil fil mai laushi | Saukewa: KQ2H12-03AS | 1 saiti |

| 15 | Sassan tushe | 1 ba. |

| A'a. | Suna | Ma'auni | Qty | Magana |

| 1 | Matsa allura | 3 ba. | T02-20A.000.000-10C T02-20A.000.000-24A | |

| Manne allon ɗaukar hoto | 6 ba n. | T02-20A.000.000-09C Ya da T02-20A.000.000-23A | ||

| 2 | Spring Small dunƙule a manne | M4x10 | 20 ba. | T02-06,001,000-02 |

| M5x12 | ||||

| 3 | dunƙule a dunƙule ciki dunƙule | M8 x1 x20 | 20 ba. | |

| 4 | Shearing ruwa | 30T | 2 ba. | T09-16.310,000-0.1.2 |

| 5 | Ciki dunƙule | M8 x1 x20 | 4 ba. |

Tsarin FANUC CNC shine tsarin CNC na musamman wanda Japan FANUC ta ƙera musamman don manufar saduwa da sifofin wannan nau'in na'ura, inganta amincin na'ura mai yawa.

I, Halayen Tsari

1. Aikin zane da naushi;

2. M duniya G code shirin don sauƙi aiki;

3. Universal RS232 misali tashar jiragen ruwa don sadarwa tare da kwamfuta dace;

4. Advanced cikakken dijital servo motor da servo tsarin;

5.10.4 ″ LCD nuni mai launi;

6. Pulse encoder Semi-loop feedback;

7. Ƙwaƙwalwar EMS: 256K;

8. Shirin filin, shirin ofishin;

9. Nunin Sinanci da Ingilishi;

10. Ayyukan kwaikwayo na hoto;

11.One babban damar PCMCIA katin domin madadin tsarin siga, tsani zane da sarrafa shirin, da kuma gane online tsari na manyan iya aiki shirin;

12. Ƙarawa a cikin mafi ƙanƙanta naúrar, matsayi gano ad servo iko don gane babban gudun da babban aiki daidai;

13. Za'a iya bayyana maɓallin aiki a kan panel bisa ga ainihin abin da ake bukata;

14. Super high gudun kama bayanai igiyoyi tare da kadan na USB dangane;

15. Babban haɗin kai, software na musamman. Wani ɗan gajeren lokaci don farawa, bayanan ba za a rasa ba idan wutar lantarki ta gaza ba zato ba tsammani;

16. Adana guda 400 na shirin.

.

2. Ƙararrawa don kuskuren lantarki kamar bugun jini.

3. Aiki na ganewar asali.

4. Ayyukan iyaka mai laushi.

5. Universal G code don shirin;

6. Aiki na ramuwa na kayan aiki;

7. Aiki na dunƙule nisa ramuwa;

8. Ayyukan ramuwa na baya;

9. Ayyukan daidaitawa karkacewa;

10. Ayyukan sakewa;

11. Ayyukan AUTO, MANUAL, Yanayin JOG;

12. Ayyukan kariyar matsawa;

13. Ayyukan kulle rajista na ciki;

14. Ayyukan shirin siga;

15. Aikin sub-shirin;

16. Ayyukan matsayi mai sauri da kulle naushi;

18. Ayyukan M code;

19. Cikakken shirin haɓakawa;

20. Tsalle mara sharadi.

Gabatarwar software na shirye-shirye

Muna ɗaukar CNCKAD daga Kamfanin METALIX. Software ɗin cikakke ne na CAD/CAM software na shirye-shirye ta atomatik daga ƙira zuwa samarwa. Tare da sarrafa ɗakin karatu na mold, sarrafa zaɓin yanayin atomatik, haɓaka hanya da sauran ayyuka, ana iya haifar da su ta atomatik ta hanyar CAD zane NC hanyoyin sarrafawa. Kuna iya cimma shirye-shiryen sashi guda ɗaya, gurɓata atomatik da cikakken kunshin.

Aiki na DrawingCNCKAD m graphics, sauki da kuma ilhama don amfani, ban da daidaitaccen aikin zane bisa ga halaye na takarda karfe, ya kara da wasu musamman zane hanyoyin kamar incision, zagaye, alwatika, dama kwana da kwane-kwane siffar, kneading, duba tace da atomatik gyara, yankan ko stamping, Sin haruffa DXF/IGES/CADL/DWG fayil shigar da dai sauransu

b) Aikin Bugawa

An nuna shi tare da naushi ta atomatik, mold na musamman, fihirisar atomatik, ƙaura ta atomatik, yankan gefen, da sauran ayyuka.

c) Aikin Shearing

Duban kwane-kwane ta atomatik da daidaita sigogin nau'in kayan, kauri, yanke guda ɗaya, yanke, da ƙaura, da sauran ayyuka, farantin aiwatarwa ta atomatik sarrafa juzu'i.

d) Bayan Gudanarwa

Yin aiki ta atomatik ko aiki tare yana rufe duk tsari: stamping, Laser, plasma, wuta, yankan ruwa da niƙa.

Advanced post aiki zai iya samar da kowane irin tasiri NC code, goyon bayan subroutine, macro shirin, kamar inganta kayan aiki hanya da mafi m mold juyawa, goyon bayan allura, injin tsotsa inji ayyuka kamar abu da zamiya block rate.

Canja wurin shirin zuwa wata na'ura kawai yana buƙatar dannawa kaɗan ta hanyar linzamin kwamfuta.Waɗannan an samo su ne daga hanyar sarrafa bayanan CNCKAD, ta hanyar kawar da manyan fayilolin kwamfuta waɗanda ke sa aikin ya fi ingantawa.

e) CNC Graphical kwaikwayo

Software yana goyan bayan duk wani kwaikwaiyo mai hoto na shirin CNC, gami da lambar CNC da aka rubuta da hannu, tsarin gyare-gyare kuma yana da sauqi sosai, software na iya bincika kurakurai ta atomatik, kamar ɓatattun sigogin matsawa da kurakuran nesa, da sauransu.

f) Canji daga NC zuwa Zane

Ko dai rubutaccen hannu ko wasu lambar NC, ana iya jujjuya su cikin zane-zane.

g) Rahoton Kwanan wata

Zai iya buga rahoton bayanai, gami da duk bayanai kamar adadin sassa, sarrafa bayanan kamar lokaci, saitin ƙira da sauransu.

h) watsa DNC

Ɗauki Windows interface na tsarin watsawa, don watsawa tsakanin PC da kayan aikin inji yana da sauƙi.

1).

2)) Goyi bayan dukan tsari na CNC kayan aiki aiki, ciki har da zane, atomatik ko m aiki, post aiki, CNC kwaikwaiyo shirin, manual da atomatik yankan, NC fayil download da upload da dai sauransu.

3) Za a iya shigar da Autocad kai tsaye, SolidEdge, SolidWork da CadKey da dai sauransu gami da duk sanannen CAD software da aka haifar da fayil ɗin hoto.

4) Software yana goyan bayan nau'ikan kayan sarrafawa iri-iri, na iya sanya sassan NC suna samar da fayilolin kayan aiki daban-daban, don na'urori da yawa a lokaci guda yayin aiki.

Sakawa ta atomatik

Lokacin da girman farantin ya fi girma fiye da wani kewayon, injin yana sake sanyawa ta atomatik, sannan ya haifar da umarnin sakawa ta atomatik; idan mai amfani yana da buƙatu na musamman, za'a iya gyarawa ko sharewa akan umarnin sake sakawa nasu.

Nisantar matsi ta atomatik

Umarnin da aka samar ta hanyar sanyawa ta atomatik wanda zai iya sanya matsi ya guje wa yankin da ya mutu, rage sharar gida; ko farantin wani bangare ne ko sassa da yawa na farantin karfe, zai iya gane aikin gujewa matsewa.

Tsage kayan sarrafa kayan

Don rage lalacewar kayan aiki a cikin tsari na stamping, ana iya amfani da fasahar sarrafa kayan tsiri, kuma ana iya amfani da kayan aikin yanke a gaba ko baya na umarnin reshe.

Dabarar datsewa

Haɗe tare da aikin bugu na gama gari, bugun atomatik wanda ke iya buga abin da ya karye a gefen gefen.

Natsuwa guda ɗaya yana motsawa ta atomatik

Tare da na'ura mai motsi mai motsi za a iya ƙirƙira ta software ta hanyar motsi ta atomatik ta umarnin NC.

Minimun mutu juyi

Zaɓin juyawa mafi ƙarancin mutu zai iya rage lalacewa ta tashar firikwensin ta atomatik kuma inganta ingantaccen samarwa.

Aikin mafi yawan nau'ikan

Aiki na naushi alwatika, naushin bevel, bugun baka da sauran keɓantacciyar hanya mai inganci.

Aiki na Ƙarfin Ƙarfin Kai

Fasalolin ƙwanƙwasa ta atomatik sun haɗa da haɗin micro ta atomatik, zaɓi na fasaha na ƙira da wadatar gano ƙararrawa da sauran ayyuka.

I) Aikin yankan atomatik

METALIX CNCKAD yana ƙunshe da ɓangaren AutoNest wanda shine saitin ainihin farantin kayan haɓakawa na haɓakawa ta atomatik, wanda zai iya fahimtar duk ingantaccen ƙarfe na ƙirar fasaha.

1. Samar da iska: matsa lamba na aiki ya kamata ya zama fiye da 0.6mPa, kwararar iska: fiye da 0.3m3 / min

2. Power: 380V, 50HZ, ikon canzawa: ± 5%, da wutar lantarki na 30T ne 45KVA, da tsauri na USB diamita ne 25mm², mai karya ne 100A. Idan wutar lantarki ba ta tsaya ba, ana buƙatar stabilizer, idan akwai wutar lantarki, ana buƙatar kariya.

3.Hydraulic mai: (SHELL) Tonna T220, Ko sauran mai don jagora da lubrication na dogo.

Man shafawa: 00 # - 0 # matsananciyar man shafawa (GB7323-94), shawara: kasa da 20 ° C amfani 00 # matsananciyar man shafawa, sama da 21 ° C amfani 0 # matsananciyar man shafawa

| Alamar | Suna | Jawabi | Zazzabi |

| Shell | EPO | 0# Matsanancin man shafawa | 21°C sama |

| Shell | GL00 | 00# Matsanancin man shafawa | 20°C kasa |

3. Yanayin yanayi: 0°C - +40°C

4. Yanayin zafi: dangi zafi 20-80% RH(un-condensation)

5. Ka nisantar da ƙarfi mai ƙarfi ko tsoma baki na electromagnetism

6. Muhalli da ƴan ƙura, babu mai guba

7. Shirya aikin ƙasa bisa ga zane na tushe

8. Ya kamata mai amfani ya zaɓi technician ko injiniya don horarwa, wanda ya kamata a kalla ya kammala karatunsa a makarantar fasaha, kuma ya tsara shi na dogon lokaci.

11.Dole ne ya shirya tushe bisa ga zane

12. A bude 65mm spanner wrench, wani goyon bayan sanda afterburner, don daidaita tushe matakin.

13. Fiye da lita 5 na man fetur mai tsafta, yawan tsumma, bindiga, mai mai mai, kamar lita 1 na kayan aikin goge-goge da gyare-gyare.

14 tare da Ф10 * 300 daya da kuma Ф16 * 300 sandunan tagulla guda ɗaya don shigarwar mold. Dogon katako (fusilage da katako an shirya su daban, amma kuma don shirya raka'o'in jigilar kaya)

15 mai nuna bugun kira (0-10mm kewayon), wanda aka yi amfani da shi don cire madaidaicin axis X da Y.

16 lokacin da kayan aiki suka isa masana'anta, shirya zirga-zirgar 20T ko crane don kayan ɗagawa

17.If V axis sanye take da ruwa chiller motor, alaka sanyaya median dole ne a shirya, da girma ne 38L.

Sauran batutuwan da ba a bayyana su ba suna buƙatar ƙarin fassarar da daidaitawa

CNC Turret Punch Machine; Turret Punch Machine; Turret Punch Machine Injin buga naushi; cnc naushi da lankwasawa; na'ura mai sarrafa turret punch press;servo drive turret punch press

| A'a. | Ƙayyadaddun bayanai | Naúrar | Samfurin Inji | ||

| Saukewa: MT300E | |||||

| 1 | Max. Punch Force | kN | 300 | ||

| 2 | Babban Nau'in Tuƙi | / | Motoci guda ɗaya | ||

| 3 | Tsarin CNC | / | FANUC CNC tsarin | ||

| 4 | Max. Girman sarrafa takarda | mm | 1250*5000 (tare da matsayi ɗaya) | 1500*5000 (tare da matsayi ɗaya) | |

| 5 | No. na Matsala | a'a. | 3 | ||

| 6 | Max. Kauri Mai Sarrafa Shet | mm | 3.2 / 6.35 | ||

| 7 | Max. Punch Diamita kowane Lokaci | mm | Φ88.9 | ||

| 8 | Main Striker bugun jini | mm | 32 | ||

| 9 | Max. Punch Hit a 1mm Taki | hpm | 780 | ||

| 10 | Max. Punch Hot a 25mm Taki | hpm | 400 | ||

| 11 | Max. Nibbling Speed | hpm | 1800 | ||

| 12 | No. na Mayar da Silinda | saita | 2 | ||

| 13 | No. na Tasha | a'a. | 32 | ||

| 14 | No na AI | a'a. | 2 | ||

| 15 | No. na Sarrafa Axis | a'a. | 5 (X, Y, V, T, C) | ||

| 16 | Nau'in Kayan aiki | / | Dogon Nau'i | ||

| 17 | Nau'in Aiki | / | Kasa 3.2mm: Cikakken goga kafaffen kayan aiki (Za a iya ƙara ƙwallan ɗagawa don lodawa azaman zaɓi) | ||

| Sama da 3.2mm: Cikakken ƙwallaye masu aiki | |||||

| 18 | Max. Gudun Ciyarwa | X axis | m/min | 80 | |

| Y axis | 60 | ||||

| Haɗaɗɗen XY | 100 | ||||

| 19 | Turret Speed | rpm | 30 | ||

| 20 | Gudun Juyawa Kayan aiki | rpm | 60 | ||

| 21 | Daidaito | mm | ± 0.1 | ||

| 22 | Max. Ƙarfin lodi | Kg | 100/150 don aikin ball | ||

| 23 | Babban Mota | kVA | 45 | ||

| 24 | Yanayin kayan aiki | / | nau'in wargajewar gaggawa mai zaman kanta | ||

| 25 | Hawan iska | MPa | 0.55 | ||

| 26 | Amfani da iska | L/min | 250 | ||

| 27 | Ƙarfin Ƙwaƙwalwar CNC | / | 512k ku | ||

| 28 | Gano yankin matattu | / | Y | ||

| 29 | Sheet-anti-tsitsi Canja | / | Y | ||

| 30 | Anti-Sheet-Lalata Canja | / | Y | ||

| 31 | Ƙimar Ƙarfafawa | mm | 5350×5200×2360 | 5850×5200×2360 | |

| A'a. | Suna | Alamar | Ma'auni | ||

| 1 | Tsarin CNC | FANUC | OI-PF | ||

| 2 | Direba Servo | FANUC | AISV | ||

| 3 | Servo Motor (X/Y/C/T axis) | FANUC | AIS (X, Y, T, C) Motoci na musamman don axis V | ||

| 4 | Hanyar Jagora | THK | HSR35A6SSC0+4200L (X:2500) | ||

| HSR35A3SSC1+2060L-Ⅱ (Y:1250) | |||||

| HSR35A3SSC1+2310L-Ⅱ (Y:1500) | |||||

| 5 | Ƙwallon ƙafa | THK | BLK4040-3.6G0+3016LC7 (X:2500) | ||

| BLK3232-7.2ZZ+1735LC7T (Y:1250) | |||||

| BLK3232-7.2ZZ+1985LC7T (Y:1500) | |||||

| 6 | Madaidaicin Ƙarfafawa | NSK/Koyo | 25TAC62BDFC10PN7B/SAC2562BDFMGP4Z | ||

| 30TAC62BDFC10PN7B/SAC3062BDFMGP4Z | |||||

| 7 | Sassan pneumatic | Haɗin gwiwa uku | SMC | Saukewa: AC30A-03D | |

| Solenoid bawul | Saukewa: SY5120-5D-01 | ||||

| Muffler | AN10-01 | ||||

| Silinda | Saukewa: CP96SDB40-80-A93L | ||||

| 8 | Tsarin Lantarki | Mai karyawa | Schneider | / | |

| Tuntuɓar | Schneider | / | |||