SMAC tana ba da cikakkun kayan aiki don layukan fenti na feshi, layukan shafa foda, layukan electrophoresis, layukan anodizing, magani kafin a fara aiki, tsaftacewa, busarwa da warkarwa, jigilar kaya, da kuma maganin iskar sharar gida da ruwan shara. Ana amfani da kayayyakin SMAC sosai a masana'antu kamar su motoci, babura, kayan kekuna, kayayyakin IT, kayayyakin 3C, kayan gida, kayan daki, kayan girki, kayan gini na ado, da injunan gini.

Bayan kayan aikin sun fita daga tanda mai narkewa, sai su shiga tsarin sanyaya mai sauri don maganin sanyaya.

Rufin Electrophoretic ya ƙunshi amfani da filin lantarki na waje don watsa barbashin fenti mai ion da aka rataye a cikin ruwa, wanda ke ba su damar shafa saman aikin kuma su samar da wani Layer mai kariya. Wannan tsari yana da fa'idodi da yawa:

Rufin da Aka Yi Amfani da Shi: Ana shafa rufin a ko'ina a saman.

Mannewa Mai Ƙarfi: Fentin yana manne da kyau a kan kayan aikin.

Ƙarancin Asarar Fenti: Akwai ƙarancin ɓatar da kayan shafa, wanda ke haifar da yawan amfani da shi.

Ƙarancin Kuɗin Samarwa: An rage jimlar kuɗin samarwa.

Ruwan da aka yi da ruwa: Ana iya narkar da fenti da ruwa, yana kawar da haɗarin gobara da kuma inganta tsaro yayin samarwa.

Waɗannan fasalulluka sun sa fenti mai amfani da electrophoretic ya zama zaɓi mai shahara a masana'antu daban-daban.

Na'urar tacewa ta ultrafiltration (UF) galibi ta ƙunshi kayan aikin membrane, famfo, bututu, da kayan aiki, waɗanda aka haɗa su wuri ɗaya. Don tabbatar da aiki na na'urar tacewa ta ultrafiltration akai-akai, yawanci tana da tsarin tacewa da tsaftacewa. Babban manufar ita ce tsawaita rayuwar ruwan fenti, inganta ingancin rufin, da kuma tabbatar da adadin ultrafiltration da ake buƙata don aikin da kayan aikin ke yi akai-akai.

An tsara tsarin tacewa ta hanyar amfani da na'urar ...

Jakar Dumama - Yin Burodi da Warkewa

Ana amfani da jakar dumama a cikin tsarin yin burodi da kuma tsaftace rufin, musamman a masana'antu kamar motoci da masana'antu. Ga taƙaitaccen bayani:

1. Aiki: Jakar dumama tana ba da zafi mai sarrafawa ga kayan aikin da aka shafa, wanda ke sauƙaƙa wa fenti ko wasu shafa fenti. Wannan yana tabbatar da cewa murfin ya manne da kyau kuma yana cimma taurin da ake so da dorewa.

2. Zane: Jakunkunan dumama galibi ana yin su ne da kayan da ba sa jure zafi kuma an tsara su ne don rarraba zafi daidai gwargwado a saman kayan aikin.

3. Kula da Zafin Jiki: Sau da yawa suna zuwa da tsarin kula da zafin jiki da aka gina don kiyaye yanayin zafi da ake buƙata, wanda ke tabbatar da daidaiton sakamako.

4. Inganci: Amfani da jakar dumama na iya rage yawan amfani da makamashi idan aka kwatanta da tanda na gargajiya, domin yana iya mayar da hankali kan zafi kai tsaye kan sassan da ake warkewa.

5. Aikace-aikace: Ana amfani da shi sosai a cikin tsarin shafa foda, fenti mai amfani da electrophoretic, da sauran aikace-aikace inda ake buƙatar kammalawa mai ɗorewa.

Wannan hanyar tana ƙara ingancin samfurin da aka gama yayin da take tabbatar da amfani da albarkatu yadda ya kamata.

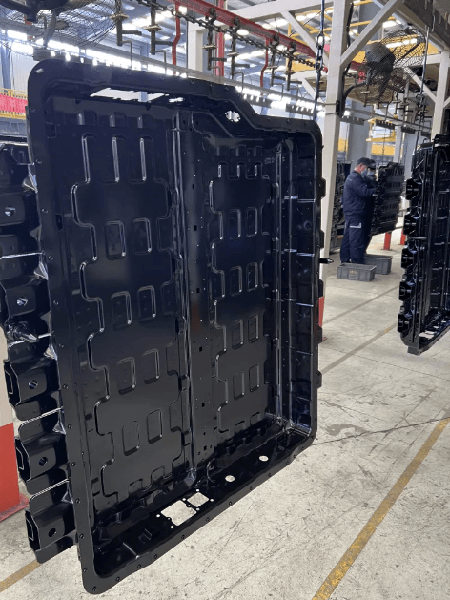

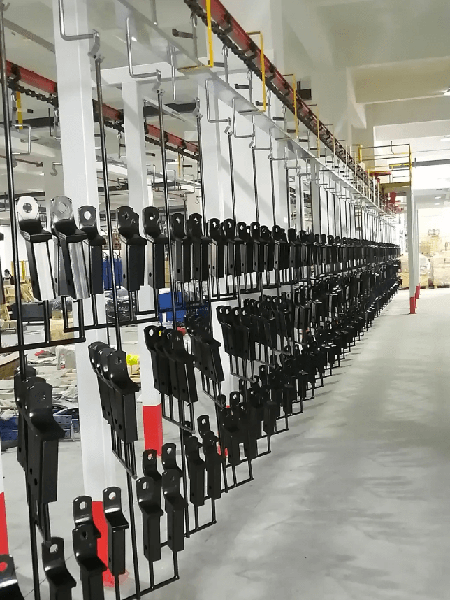

Tsarin jigilar kaya

Tsarin jigilar kaya na sama ya ƙunshi muhimman abubuwa da dama, ciki har da tsarin tuƙi, na'urar ɗaukar nauyi, sarƙoƙi, hanyoyin madaidaiciya, hanyoyin lanƙwasa, hanyoyin telescopic, hanyoyin dubawa, tsarin shafawa, tallafi, rataye masu ɗaukar kaya, tsarin sarrafa wutar lantarki, da na'urorin kariya daga wuce gona da iri. Babban ayyukansa sune kamar haka:

1. Aiki: Lokacin da injin ya juya, yana tuƙa layin ta hanyar na'urar rage gudu, wanda hakan ke ba da ƙarfi ga dukkan sarkar jigilar kaya ta sama. Ana dakatar da kayan aikin daga na'urar ta amfani da nau'ikan rataye daban-daban, wanda ke sauƙaƙa sauƙin sarrafawa da aiki.

2. Keɓancewa: Tsarin layin jigilar kaya yana ƙaddara ta takamaiman yanayin aiki da kuma tsarin samfurin, wanda ya cika buƙatun samarwa yadda ya kamata.

3. Aikin Sarka: Sarka tana aiki a matsayin ɓangaren jan hankali na na'urar jigilar kaya. Ana sanya tsarin shafawa ta atomatik akan sarkar don tabbatar da cewa duk haɗin gwiwa masu motsi suna samun madaidaicin adadin mai.

4. Maƙallan rataye: Maƙallan rataye suna tallafawa sarkar kuma suna ɗaukar nauyin abubuwan da ake jigilar su a kan hanyoyin. Tsarin su yana ƙayyade ne ta hanyar siffar kayan aikin da takamaiman buƙatun tsari. Maƙallan rataye suna yin maganin zafi mai dacewa don tabbatar da cewa suna jure wa amfani na dogon lokaci ba tare da fashewa ko lalacewa ba.

Wannan tsarin jigilar kaya yana ƙara inganci da aminci a aikace-aikacen masana'antu daban-daban.

Lokacin Saƙo: Yuli-25-2025